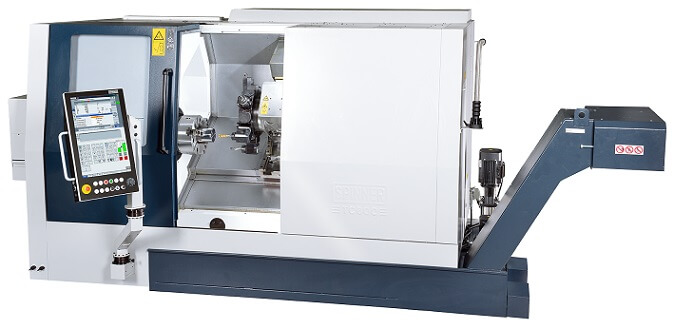

TC – Universal Turning

TC800-110-MC

immediately – on stock

2022

Siemens 840DE SolutionLine

main Factory Sauerlach

New

8043813

FREE FROM EXPORT ORDER:

Universallathe SPINNER TC according to following configuration:

Approx delivery time 1 Week

TC800 BASIC MACHINE with strokes X=360mm Z=900mm

in 45 degree inclined bed design

with hardened and ground slideways

equipped as a SINGLE-SPINDLE-TURNING MACHINE with turret

WITH driven tools

in TCXXX-MC version

INDEXING TURRET – WITH driven tool stations

all tool stations can be driven on the inner circle of turret disk. If one circle all posiitons can be with live tools

only the station in working position is driven

designed as servo turret

Swivel speed as adjustable CNC axis with feed potentiometer

Tool holder on turret system DIN 69880 / DIN ISO 10889, size VDI50

AXIAL ARRANGEMENT at the front of the turret

Number of tool stations in the turret: 12

SPINDLE 1 in version up to 2,600 rpm – 110mm

As belt-driven spindle with 2-speed gear unit

with hollow shaft measuring systems mounted directly on spindle shaft for C-axis operation

with hydraulic hollow clamping cylinder, bar passage 110mm,

Speed range 0-2,600 rpm , Pmax 63 kW / 2250Nm

Spindle nose DIN55026/A11

POWER CHUCK by SMW-Autoblok

D=315mm 3-jaw, BBD model

incl. adapter flange, draw tube adapter, set of soft jaws mounted on main spindle

Set of hardened TOP JAWS suitable for chuck on main spindle

TAILSTOCK can be towed in the program by coupling to Z-axis, hydraulically clamped to the bed. With

additional integrated hydraulic quill and bearing for fixed tip.

Hydraulically adjustable contact pressure.

Version with SIEMENS control with the following features:

Attention: Siemens general conditions for softwareproducts are valid:

www.sw.siemens.com/en-US/sw-terms/base/eula/

SIEMENS 840DE control system with the following basic scope:

– SPINNER – SPIOS 24″ Touch Control Panel for I4.0 applications

– Height-adjustable, rotatable and tiltable control panel for optimum ergonomics

– incl. engraving cycles

– 24″ liquid crystal colour flat panel display with Multi touch functionality

– User memory 2 GByte

– 15 zero offsets

– 1 free USB interface

– Standard Ethernet interface

PRIMARY LANGUAGE: Russian

SECOND LANGUAGE: German

MULTI-FUNCTION CONTROL HANDSET with integrated display

to display

– position of the active axis

– active increment

– spindle speed

– current feed

and the following integrated operating functions:

– NC start/stop, spindle start/stop, feed start/stop

– axis selection keys

– direction keys/ rapid traverse superimposition

– reset/Single block

– feed rate override

SHOPTURN work step programming

Attention: Linear tooling ahead turning center (Microturn behind spindle-center) are not

supported by ”Shop-Turn” graphics. They have to be programmed in DIN system within Shop-

Turn environment.

3D SIMULATION of finished parts

RESIDUAL MATERIAL DETECTION

and machining of contour pockets

SIMULTANEOUS RECORDING of the machining process

SIGNAL LAMP on top of the machine in three colors red / yellow / green as a status indicator

Functions:

Red: machine alarm

Yellow: End of part program / end of bar / parts pallet empty

Green: The program is running in automatic mode

CHIP CONVEYOR

as hinged belt conveyor exiting to the right, incl. integrated coolant tank and

feed pump. Universal design variant

Rinsing gun in working area

MEASURING PROBE for tool measurement in the working area incl. quick-change coupling

The probe can be used for setup operation in the working area to

measure the tools in X/Z direction.

Attention: Collision considerations with turrets can lead to restrictions depending on the

design of the tools on the disc.

Version for standard chuck sizes

UNIMAG interface for bar-loading magazine

STANDARD DOCUMENTATION IN GERMAN

consisting of machine manual and CNC manuals

is supplied in digital form on the control. Paper manuals subject to additional charge

STANDARD PAINTWORK two colours in light grey RAL7035 and blue grey RAL5008

EUROPA-STANDARD electrical version as follows:

Operating voltage 3x400V +/-10%

Mains frequency 50Hz (+/-2%)

TN network (5-wire)

+ BIG PACKAGE OF TOOLDERS, MILLING-HEADS AND ACESSORIES.